Turnaround Services

A turnaround is a scheduled event where an entire process unit of an industrial plant (refinery, petrochemical plant, power plant, pulp mill, etc.) is taken off-stream for an extended period of time for repair or renewal. Turnaround is a blanket term that encompasses more specific terms such as inspection & testing, debottlenecking projects, revamps and catalyst regeneration projects.

Turnarounds are expensive in terms of lost production while the processing unit is offline and in terms of direct cost for labor, tools, equipment and materials to execute the project. Turnarounds can affect the company’s bottom line if mismanaged.

PK Technology provides high quality, comprehensive turnaround services and solutions. We use an innovative approach to our turnaround inspection services and planning assessment tools in order to reduce your turnaround cost and keep your turnaround on, or ahead of, schedule. PK is the only contractor that has a digital turnaround tool that provides a pre-turnaround assessment and post-turnaround documentation the minute activities are complete.

We Provide:

- Inspection Services

- Flange & Blind Tracking

- Weld Tracking

- Task Tracking

- Vendor Surveillance

- Turnaround Assessments

Inspection Services

As a leading inspection contractor, we are the first choice for clients requiring effective mechanical integrity management. Through the use of our proprietary technology and experienced staff, we have the resources to achieve your inspection, data management and safety goals.

- API 510, 570,653

- NACE Level I, II and III

- CWI, QA/QC

- NDT – PT, UT, MT

- Rope Access

Flange & Blind Tracking

PK Technology Flange Management Tracking can assist with all turnaround processes. Planning is the most critical part of turnaround projects. PK Technology works alongside the client’s on-site TAR Planning Group / Engineering Group to increase the efficiency and trackability of the project. Through the use of our proprietary technology, we are able to reduce the flange management process by 42% vs traditional paper tag methods.

Task Tracking

PK Technology Task Tracking delivers transparency through management dashboards and digital wall charts to provide real-time visibility to enable managers to make intelligent and informed decisions faster so the turnaround stays on schedule and on budget. The Digital Turnaround Manager offers the ability to import P6 schedules directly into intelliSPEC™ and export reports back to P6 or other sources such as Excel, Word, PDF, etc.

The Turnaround Assessment

Keep a turnaround on budget and on schedule without compromising quality workmanship with PK Technology. We utilize a turnaround assessment tool that is a series of comprehensive turnaround assessments coupled with innovative mobile technology and leadership focused action to close all gaps pre-turnaround.

A STATEMENT HEARD AMONG TURNAROUND PROFESSIONALS

"For a turnaround you get to pick two of the three: on budget, on schedule or quality workmanship."

This statement, while believed by many, is false!

You can have all three plus job safety, an environmentally sound effort and an outcome that will deliver long term plant reliability!

The question is how?

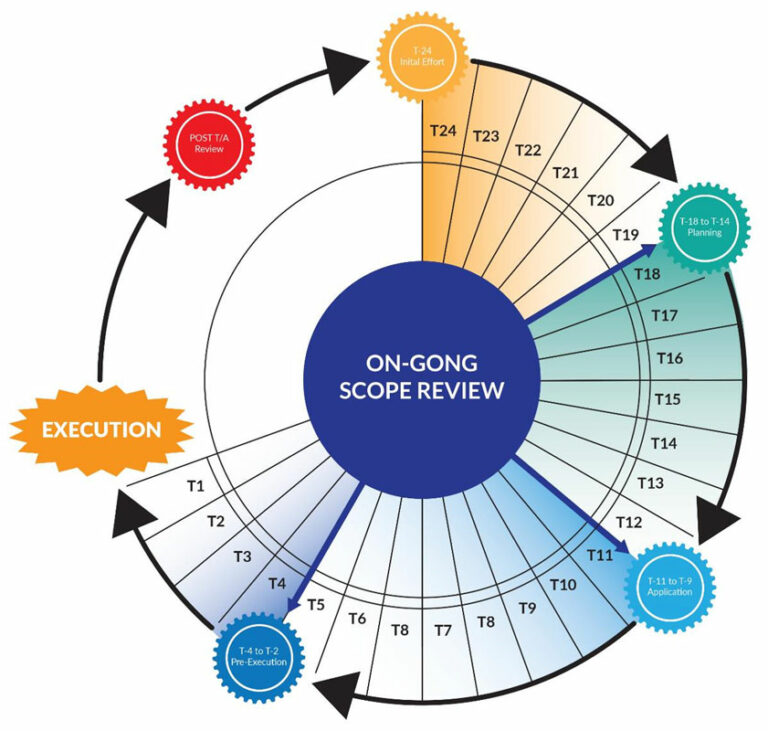

The Turnaround Assessment Cycle

T-24

Initial Effort

This assessment is conducted at the very beginning of turnaround planning. It is designed to assure that a team has been assembled and there are work assignments made to develop documentation that will direct the remaining effort prior to and during execution. The assessment is also designed to assure that the team understands what is required to assemble the turnaround work scope.

T-18 to t-14

Planning

The assessment at this point in time deals with the development and completion of the detailed documentation which will support the following two stages. This assessment is also checking the development of the turnaround work scope assuring that work items are properly vetted for inclusion.

T-11 to t-9

Application

At this level, the assessment addresses the status of the preparation activity associated with the categories and subcategories within the developed documentation. Once again there is a detailed check on the status of the work scope which should be almost to the point of “scope freeze.”

T-4 to t-2

Pre-execution

This is the final and last assessment before the actual execution of the work. In this assessment, all the details need to be in place or completed within a short period of time. Significant gaps identified here have the potential, if not corrected, to have a negative impact on the execution effort.

T-1

Post Audit

Following a turnaround, it is imperative to conduct a lessons learned review by a third party. This effort is designed to identify things that went well so that they can be repeated at the next turnaround. It is also designed to identify opportunities for improvement so that these issues can be corrected the next time. Internal efforts of this sort can suffer due to individual or group bias and should be avoided. Without a post-execution review, there will be no value added to future turnarounds since the information will be lost.

Turnaround Assessment Topics

- General Logistics

- Strategy

- Outage Preparation

- Staffing

- Safety

- Security and Transportation

- Industrial Hygiene

- Environmental

- Process Safety Management

- Contracts and Contractors

- Outages and Their Capital Projects

- Cost Control

- Inspection

- Procurement of Material

- Materials Management

- Shops Repairs

- Communication Including Radios

- Information Technology

- Training

- Documentation

- Operations (also called Production)

- Scope Related Logistics

- Outage Planning

- Outage Preparation

- Staging

- Transition

- Execution – Effectiveness and Efficiency

Support - Meetings

- Testing, Final Inspection and Approval

- Housekeeping

- Post Outage

- Miscellaneous Logistical

- Components

- Forms

- Other Miscellaneous Items